The funds will be used for strategic radiation-hardened microelectronics fabrication via a Defense Microelectronics Activity-accredited manufacturing process and support 90nm technology development in Honeywell’s Minnesota microelectronics foundry. Discover the next generation of strategies and solutions to streamline, simplify, and transform finance operations. Artificial intelligence and 3D scanning vision systems assist independent workstations in fully automated continuous operations, replacing adhesives with air to achieve environmentally friendly shoe manufacturing. The surface modification treatment of conductive materials for LED chips and substrates in the semiconductor and optoelectronic industries includes etching, surface modification, purification, coating, or sterilization processes for integrated circuits. When implementing manufacturing technology, there are several important factors to consider. Manufacturing technology should foster greater transparency and collaboration across all product development teams to enhance value and decision-making, lower costs, ensure sustainability, and get to market faster.

What are important features of an AP automation software?

Tipalti integrates with top-end Oracle ERP and SAP S/4 HANA, which are unified enterprise resource planning systems used by the largest enterprises and growing mid-sized companies needing a scalable AP automation solution. T3 Micro is a manufacturer and wholesaler of hair styling tools in the beauty industry. Getting automated payment reconciliations for large batches with up to thousands of invoices and multiple payment methods saves your manufacturing ap technology company significant time and can accelerate your monthly close by 25%. Remember that successful manufacturing technology implementation involves a holistic approach, as outlined in the considerations above.

Adaptive Patterning Software Ecosystem

This supplier portal will display the history of invoices and payments for invoice management and supplier invoice receipt, approval, and payment status. Since its inception in 1978 Tecnikabel has focussed its expertise in the design and manufacture of cables for use in the machine tool, robotic and Industrial automation applications, concentrating on the supply of bespoke and custom cable. The manufacturing facility has Bakery Accounting the capacity to manufacture a wide variety of cable types and holds a wide range of approvals including UL & CSA, VDE, Desina and Lloyd’s Register.

Tip Sheet: 5 Ways payables automation improves your organization’s financial health

- An extensive range of accessories to support one of the industry’s broadest ranges of IP68 rated glands from Bimed.

- T3 Micro is a manufacturer and wholesaler of hair styling tools in the beauty industry.

- AP Technology supply an extensive range of Cable Glands and Accessories from Bimed in the UK.

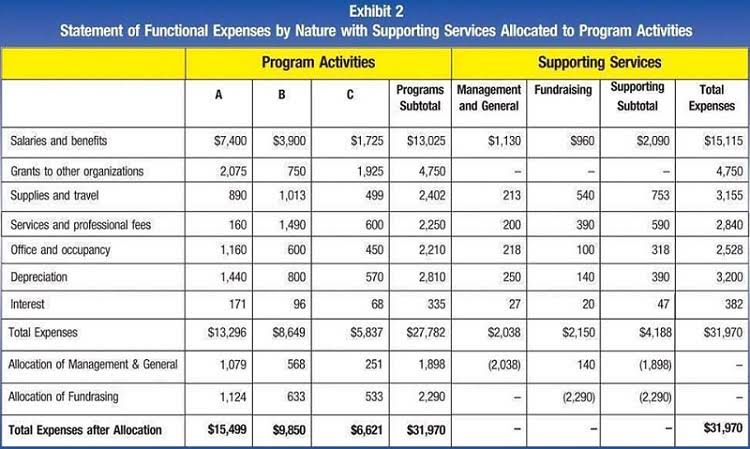

- Manufacturers manage many suppliers, vendors and customers, which results in a high volume of different types of invoices, payments and payment forms.

- We get that manufacturing companies like yours are tasked with complex purchasing needs, from managing large invoice volumes to ensuring compliance with CIS (Construction Industry Scheme) regulations.

Intelligent automation helps introduce visibility into accounting processes and identify system breakdowns. This increased visibility allows accounting department leaders and C-level executives to view the impact of those processes on the bottom line and make highly strategic decisions based on accurate, up-to-the-minute information. PDI and others who have implemented AP automation technology have found that employees spend less time online bookkeeping on process-oriented tasks, and thereby are empowered to add real value to the organization. Equipment, computer software, and tools comprise the bulk of manufacturing technology companies use to market a product. Through advanced manufacturing technology, companies can leverage the insights they’ve gathered to benefit everyone involved, including the consumer. Across industries, manufacturing technology paves the way forward, enabling companies large and small to improve their output every step of the way.

Manufacturers manage many suppliers, vendors and customers, which results in a high volume of different types of invoices, payments and payment forms. To combat this high volume, one of the most significant steps a manufacturer can take toward a lean accounting process is to integrate AP automation technology with its existing ERP solution, such as Microsoft Dynamics, to achieve intelligent automation. Workflow routing can eliminate several days of pre-processing time in a variety of organizations. Using a permission-based system, routing and approval rules can be modified with a few keystrokes in vendor and customer records. Once modified, newly designated approvers can be regularly reminded via e-mail about invoices awaiting their action. The best solutions also allow alternate approvers to be designated and notified if primary approvers are absent.

- Founded in 2001, we are a franchised specialist supplier of interconnect products including cable, connectors, cable assemblies, wire and wire management products to a broad range of industries and requirements.

- These include the initial investment, integration complexities, resistance to change, data security concerns, and the perception of a steep learning curve.

- UK Stock We hold over 750 cable types in stock at our London warehouse and through strategic partnerships have access to 1,000s more.

- In addition, 41 percent reported improved process optimization and control after deploying AI technology.

- Your vendor must do more than take the paper out of the process, and work to adapt its solutions to fit the unique aspects of your operating environment, suppliers and customers.

USDA Rural Development Business Programs

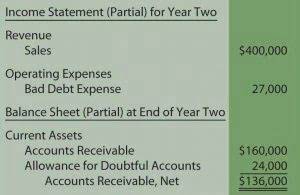

Advanced OCR systems in manufacturing can recognize and process various invoice formats and languages, enhancing the efficiency of AP operations. Slow payments can also lead to disputes, strained relationships, and potentially loss of supplier trust and loyalty. In the manufacturing sector, where timely procurement of materials is critical, any delay in payments can disrupt the entire production schedule.

Simplify payments

Moreover, technology evolves at lightning speed and should be revisited and evaluated regularly to meet customer needs, new innovations, and industry developments. At AP Technology we have over 40 years of combined industry experience in the production of bespoke cable assemblies to customer’s requirements. We can help you produce the cable assembly appropriate to your application, balancing the needs for optimum performance with value for money. Staying competitive means constantly improving efficiency, and AP automation plays a key role.